Bend line shift bls the distance from the outside mold line to the original bend line on the flat pattern this is used to calculate the backstop location when working off of a flat pattern.

Oml sheet metal.

Cells on the right will output the desired values.

Outside offset osos the measurement from the surface of the outside radius to the apex of the outside mold lines.

You only have to insert interior angle flange lengths k factor inside radius and material thickness.

8 am 5 pm saturday.

At oml metals ltd we specialise in sheet metal ductwork and steel fabrications.

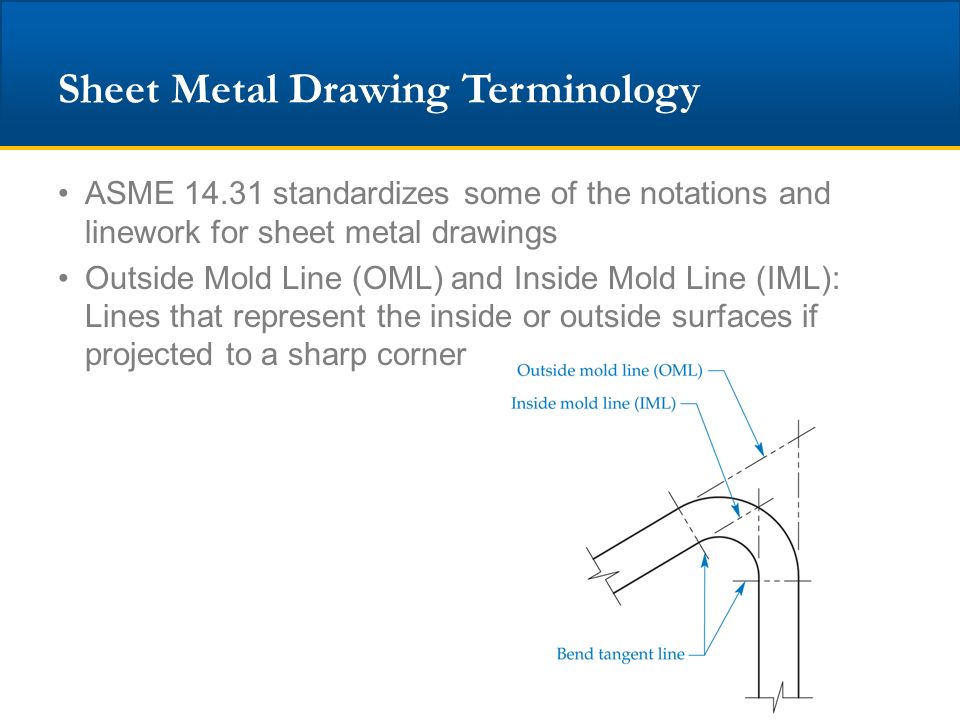

Inner and outer mold line definition in sheet metal operation 10 05 2012 5 50 am i am agree with lyn iml the inside dimensions of sheet metal part and oml is the outer like a square or u shape to be inserted in a given dimension.

Get to know them better to learn advance concept easily.

Request a quote for your metal today from our los angeles location below.

Here end the fabrication formulas for sheet metal up next we ll be seeing some of the terminologies in sheet metal that you ll need.

First the casting alloys those suitable for casting in sand permanent.

Outside mold line or oml the intersection of two outside surfaces of a part extended past the bend radius.

However some of the larger aircraft use sheet stock which may be as thick as 356 inches.

When calculating the outside offset use the included bend angle.

Most sheet metal materials will conform to the calculations.

This page also includes a link to a on line calculator.

The following illustration shows the equation calculation for determining the bend line to mold allowance when forming sheet metal.

The various types of aluminum may be divided into two general calluses.

Most drawing dimensions for formed sheet parts are to the outside mold line.

Bigger volume of metal removed less time to machine the workpiece the market requires safe clamping which could at the same time possibly avoid the deformations of the piece itself.

8 am 12 pm 8300 san fernando road sun valley ca 91352 phone 818 729 3333.

Outside mold line oml a line that runs parallel to the outside of the workpiece.

Most aluminum alloy sheet stock used in aircraft construction range from 016 to 096 inches in thickness.

With this free online tool we quickly get the sheet metal bend deduction and therefore the sheet metal blank initial flat length from the finished part measurements.